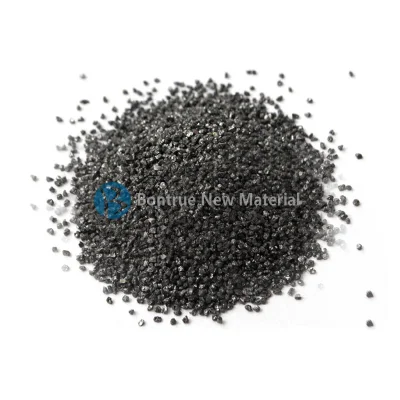

9.0 High Hardness Abrasive Grade 98% Sic Black Silicon Carbide Grain for Polishing Grinding

Overview Product Description Product Parameters Size and Standard Packaging & Shipping Packing for Silicon carbide: It i

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | Black SIC |

| Hardness | Superabrasive |

| Product | Green / Black Silicon Carbide |

| Transport Package | Bag |

| Specification | custom-made |

| Trademark | Bontrue |

| Origin | Henan, China |

| HS Code | 2849200000 |

| Production Capacity | 80, 000 Tons/Year |

Product Description

Product Description

| Silicon carbide is an inorganic substance with a chemical formula of SiC. It is made by high temperature smelting of raw materials such as quartz sand, petroleum coke (or coal coke), and wood chips (salt is needed to produce green silicon carbide) through a resistance furnace. Silicon carbide also exists in nature, a rare mineral, moissanite. Among the non-oxide high-tech refractory materials such as C, N, and B, silicon carbide is the most widely used and most economical one. Green silicon carbide is made from petroleum coke and high-quality silica as the main raw material, adding salt as an additive, and smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, and its mechanical strength is higher than that of corundum. |

| Black Silicon Carbide | ||||

| Item | SiC | Fe2O3 | Free Carbon | SiO2 |

| SiC97 | ≥97% | ≤1.0% | ≤0.5% | ≤1.5% |

| SiC95 | ≥95% | ≤1.5% | ≤1% | ≤2.5% |

| SiC92 | ≥92% | ≤2.0% | ≤2.5% | ≤3.5% |

| SiC90 | ≥90% | ≤2.5% | ≤3% | ≤4.0% |

| Green Silicon Carbide | ||||

| SiC99 | ≥99% | ≤0.2% | ≤0.2% | - |

| Standard | Particle Size | SiC ≥ (%) | F.C ≤ (%) | Fe2O3 ≤ (%) |

| GB | F4-F90;P12-P100 | 99.10 | 0.20 | 0.20 |

| JIS | 8# - 220# | 98.0 | / | / |

| OCT | 10#;12# | 98.0 | 0.4 | (Fe) 0.3 |

| GB | F320-F500; P400 | 97.5 | 0.30 | 0.50 |

| JIS | 240# - 3000# | 96.0 | / | / |

| OCT | M40-M14 | 98.0 | 0.4 | (Fe) 0.2 |

| The Usage of Silicon carbide: 1. In the electrical industry, silicon carbide can be used as lightning arrester valve body, silicon carbon electric heating element, far infrared generator, etc.2. In the aerospace industry, gas filters and combustion chamber nozzles made of silicon carbide have been used in rocket technology.3. Low-grade silicon carbide can be used as steelmaking deoxidizer and cast iron additive.4. In the carbon industry, silicon carbide can be used to produce bricks for iron-making blast furnaces, such as graphite silicon carbide, silicon carbide bricks combined with silicon nitride, etc.5. In the production of graphite electrodes, silicon carbide is also used as the coating refractory sintering material of oxidation-resistant coating electrodes to add the coating's ability to withstand sharp changes in temperature.6. In the manufacture of special carbon materials-biochar, propane and trichloromethylsilane are often used as gas materials. After high temperature pyrolysis, the silicon-containing pyrolytic carbon coating is accumulated on the graphite substrate to add products. The hardness, strength and wear resistance. |

| Bontrue New Materials Co., Ltd. is China's leading supplier dedicated to providing its customers with the quick quotes, superior quality refractory products and abrasive products, competitive prices and fastest possible deliveries of refractory engineering solutions. Founded in Zhengzhou in east-central China, with over years of expertise in refractory engineering, the company is committed to research & development, and providing a range of high quality, innovative, cost-effective refractory products and engineering solutions. At present, its main products are tabular alumina, blast furnace slag, refining slag, taphole clay, tapping hole block and nozzle brick, sic. As a ISO9001:2015 certified supplier, possessing sophisticated production lines and inspection equipments, providing diverse lines of variety refractory products backed by expert R&D technical support, we develop closer customer relationships and taking on a larger role in the total supply and manufacturing chain. Exporting first-class refractory products to the world as a mission, as a pilot enterprise of One Belt and One Road initiative pilot enterprise, Bontrue grasps the opportunity to vigorously develop overseas markets. Our products have been exported to Europe, Asia, Africa, South America and Middle Eastern countries, which enjoys good reputation. |

1. 7*24 hours on-line service.

2. Continuously monitor customers' usage.

3. Engineers on site for after-sale retun visit and providing techinical support.

4. Strong production capacity and plenty of inventory to ensure further orders.